Turnkey Teaching Laboratory Solutions

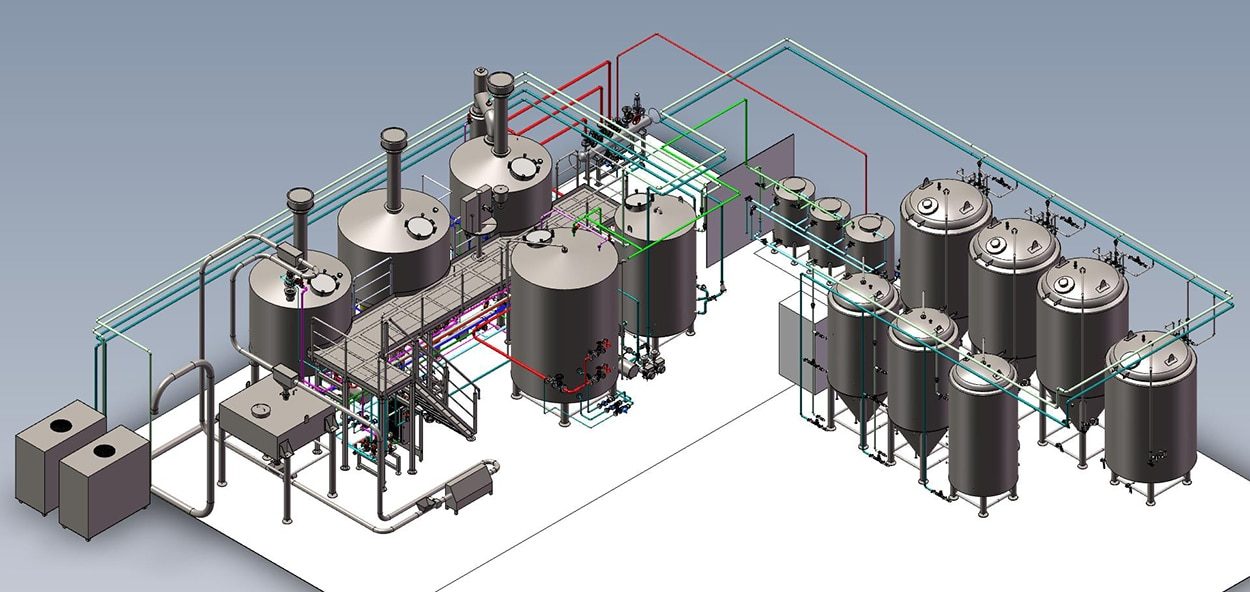

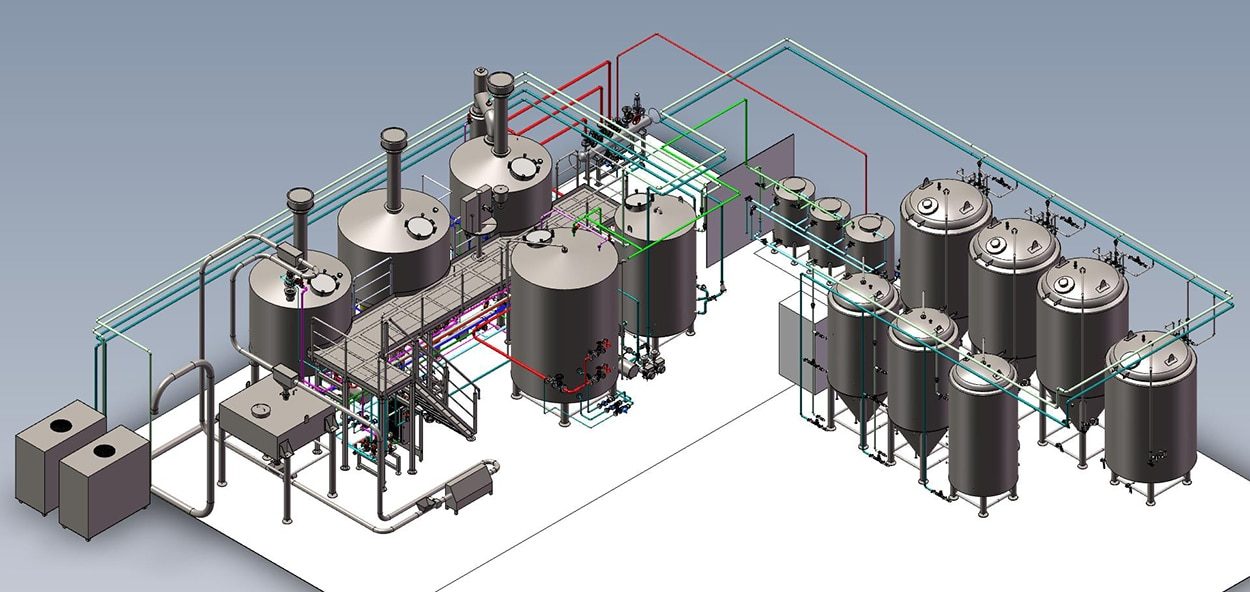

In response to the current needs of universities and various research institutions, ZYB Craft has timely launched laboratory and factory-type beer experimental equipment to meet different levels of research and development needs. According to the current industry development status, we timely launch factory teaching projects to meet the needs of relatively large production, with an output between 500-2000l. The equipment design and matching meet the development trends and process requirements of normal craft breweries, simulating small and medium-sized configurations and operating habits of a craft brewery are designed to meet the teaching requirements while achieving appropriate large-scale production.

Basic Configuration

Configuration chosen based on our experience

Capacity Specifications

50-300L/Batch, 1/2-3BBL/Batch

Brewhouse Configuration

2, 3,4 vessels system

Heating Method

Electricity, steam, direct fire

Heating Method

Electricity, steam, direct fire

Degree of Automation

Manual, semi-automatic, fully automatic

Optional Configuration

Small packaging system

Degree of Automation

Manual, semi-automatic, fully automatic

Optional Configuration

Small packaging system

Basic Configuration

Configuration chosen based on our experience

Hot Liquid Tank

Yeast System

Cold Liquid Tank

Brewhouse Equipment

Air Pressure System

Fermentation Tank

Bright Tank

Stainless Steel Manifold

Control Cabinet

Plate Heat Exchanger

Equipment Features

Cutting-Edge Brewery Equipment Design

- It has simple and flexible operation, low power consumption, and small floor space.

- It can be designed as required to facilitate science and scientific research.

- Develop students' practical skills and present the craft of brewing in a brewery.

- Professionals come to install and debug to provide customers with a full range of services.

- We can provide customers with customized beer processing small-scale testing and pilot-scale system equipment.

Why Choose Us

Reasons to Partner With Us

The design of each equipment is customized for you, and a reasonable layout plan is provided according to the size of the factory. Combining existing resources and development, formulate product structure positioning to achieve high efficiency, high yield, and high flexibility.

The design is based on the layout of the entire plant, and a reasonable installation layout is developed from the perspective of high efficiency and energy saving, reducing system maintenance requirements, and ensuring optimal operation of the system. Provide complete service solutions, install, debug, operate, and maintain on-site equipment, provide long-term parts supply and regular return visits, and understand the operating status of the equipment.