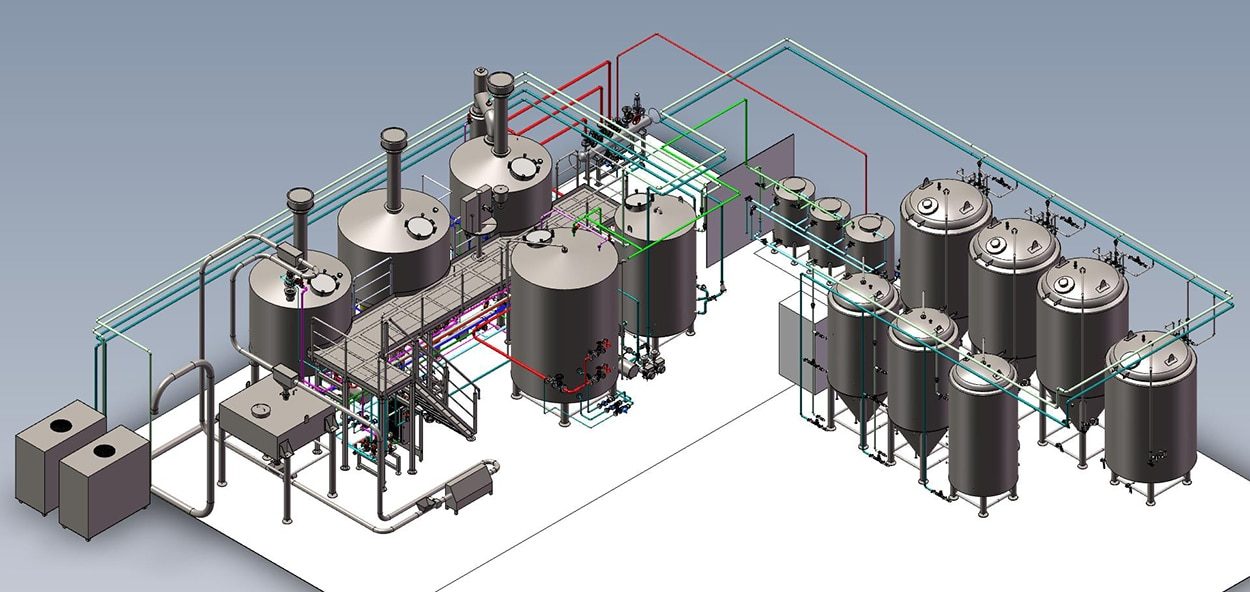

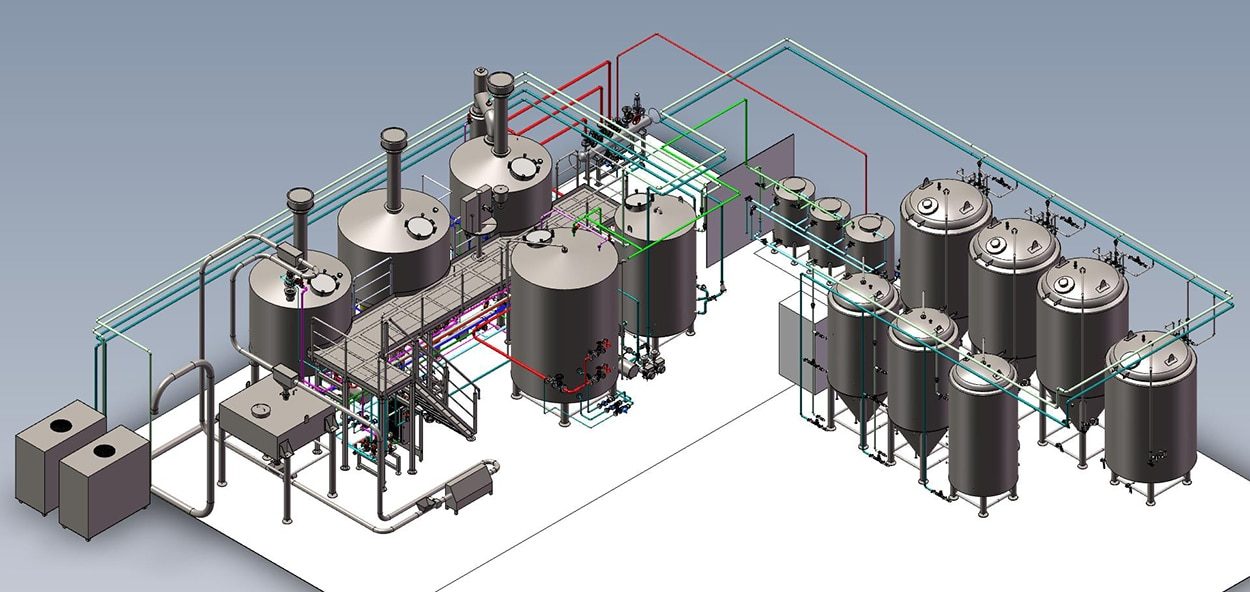

Turnkey Craft Brewery Solutions

Building a brewery from the ground up can be a daunting task, and you can be overwhelmed by the amount of work required to get it up and running. From designing a brewery layout to selecting equipment, sourcing materials, and obtaining permits, there is a lot to do. This is where turnkey solutions come in. The brewery turnkey solution service provided by ZYB Craft can provide you with everything you need to set up and operate your brewery from start to finish, making the process smoother, faster, and more efficient.

Craft Brewery Configuration

Capacity Specification

10-100HL

Brewing Efficiency

1-10 Brew/Day

Brewhouse Configuration

2, 3, 4 Vessls

Heating Method

Steam Heating

Mashing Efficiency

90-95%

Control Level

Semi, Fully Automatic

Mashing Efficiency

90-95%

Basic Configuration

Configuration chosen based on our experience

Hot Liquid Tank

Yeast System

Cold Liquid Tank

Brewhouse Equipment

Air Pressure System

Fermentation Tank

Bright Tank

Stainless Steel Manifold

Control Cabinet

Plate Heat Exchanger

Optional Configuration

Can be freely selected according to production needs

- Wet Milling System

- Bottling Lines Range

- Hops Dosing Unit

- Wet Milling System

- Bottling Lines Range

- Hops Dosing Unit

- Fully Automatic System

- Yeast Assimilation System

- CO2 Recovery System

- Fully Automatic System

- Yeast Assimilation System

- CO2 Recovery System

Technical Advantages

Cutting-Edge Brewery Equipment Design

- High wort yield.

- Fully automated production operations.

- Low energy consumption, the lowest raw material consumption under the same output target.

- Reasonable pipeline layout design ensures the quality of beer and improves the utilization rate of raw materials.

- According to the needs of specific regions, a pressure boiling process can be adopted to increase the boiling intensity of the wort.

- According to the specific tank layout, add an operation platform, takeover plate, or pipe gallery system.

- The internal heating system fully provides the wort evaporation rate.

- According to the actual brewing needs of customers, other supporting equipment can be appropriately added or combined.

- The internal heating system fully provides the wort evaporation rate.

- According to the actual brewing needs of customers, other supporting equipment can be appropriately added or combined.

- While satisfying the existing production, the refrigeration system also has a sufficient margin to meet the needs of future development.

- The rational design of the equipment reduces the energy consumption of the equipment and improves the thermal efficiency of the steam system.

- The automatic control system monitors the production process with management functions and graphical formula editing functions to ensure high stability of product quality.

- Combined with on-site equipment, full-automatic and semi-automatic process control can be selected, which can improve efficiency and avoid misoperation.

Why Choose Us

Reasons to Partner With Us

The overall design of each project prioritizes meeting the customer’s basic brewing process needs, while also better integrating special process requirements. Equipment processing uses high-quality tooling and exquisite skills to ensure that all production process equipment meets the basic requirements of the brewing process and the diverse needs of different customers. We insist on strict control of the production process and strict supervision of all auxiliary machines, accessories, etc. Control to ensure strict management results during the production process.

We have a professional construction team to ensure that any project is delivered with quality and quantity under the agreed conditions and time requirements. Our company’s professional process technicians will work with all customers to carry out full and detailed installation, debugging, and trial brewing until the entire project meets the customer’s expectations and is perfectly run and delivered.